In industrial applications, control and regulation of fluid flow are critical to ensuring the efficiency, safety, and accuracy of operations. Among the many valve types used for instrumentation, the 3-way manifold valve stands out as an essential component in pressure and flow measurement systems. This article will provide an overview of 3-way manifold valves, explaining their construction, function, and importance in industrial settings.

What is a 3-Way Manifold Valve?

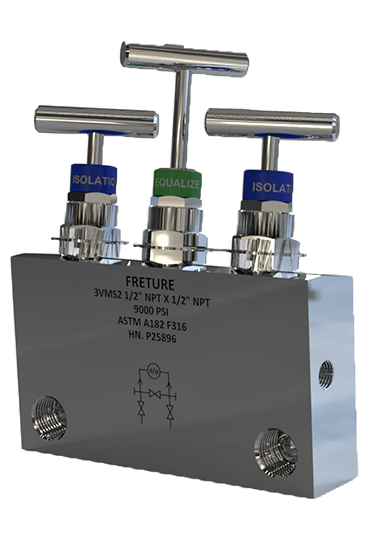

A 3-way manifold valve is a compact, multi-port valve assembly designed primarily for use with pressure measurement instruments such as differential pressure (DP) transmitters, gauges, and switches. It features three main ports, each of which serves a specific function in isolating, equalizing, or venting process fluids. These valves are often used in conjunction with DP transmitters to measure the difference in pressure across two points in a system.

|

| 3 Way Manifold Valve Manufacturer in Mumbai, India |

The three main ports in the valve are:

- High-Pressure Port: Connects to the high-pressure side of the process fluid.

- Low-Pressure Port: Connects to the low-pressure side of the process fluid.

- Equalizing Port: Allows for equalization of pressure between the high and low sides during maintenance or calibration procedures.

Working Principle of 3-Way Manifold Valves

The 3-way manifold valve works by directing the flow of process fluids through its three ports. In normal operation, the high and low-pressure ports are connected to the DP transmitter, allowing it to measure the pressure differential. When calibration or maintenance is required, the equalizing valve is opened, creating a bypass that equalizes the pressure on both sides of the transmitter. This prevents damage to sensitive instrumentation and ensures accurate readings.

The valve assembly also often includes venting capabilities, which allow operators to release any trapped air or fluid from the system. This feature is especially important when dealing with pressurized systems, as it helps maintain safety and efficiency.

Applications of 3-Way Manifold Valves

3-way manifold valves are used in a variety of industries where precise control and measurement of fluid pressure are necessary. Common applications include:

- Oil and Gas Industry: For monitoring pipeline pressures, especially in hazardous environments.

- Chemical Processing: Ensuring accurate pressure measurements in corrosive or high-temperature environments.

- Power Generation: Used in steam and water systems to maintain operational safety.

- Water Treatment: Controlling and measuring pressure in filtration and purification processes.

Materials and Construction

To meet the varying demands of different industries, 3-way manifold valves are constructed from materials suited to specific environments. Common materials include:

- Stainless Steel: For resistance to corrosion and high temperatures in aggressive environments.

- Carbon Steel: Ideal for high-pressure applications that require durability and strength.

- Alloy 400 (Monel): Used in situations where resistance to acidic or corrosive fluids is necessary.

The selection of material depends on factors like process fluid type, temperature, and pressure conditions.

Advantages of Using 3-Way Manifold Valves

Improved Measurement Accuracy: By providing a reliable way to isolate and equalize pressure, 3-way manifold valves ensure that pressure readings are accurate and that instruments are protected from overpressure damage.

Space-Saving Design: Instead of using multiple valves for isolation and venting, 3-way manifold valves combine these functions into a compact design, saving space and reducing the need for multiple components.

Reduced Maintenance: The ability to isolate and equalize pressure during calibration reduces wear and tear on instrumentation and extends the life of pressure measurement devices.

Enhanced Safety: These valves improve safety by allowing pressure equalization before maintenance, reducing the risk of sudden pressure surges or equipment failure.

In industries where accurate pressure measurement and fluid control are essential, 3-way manifold valves play a key role. Their ability to isolate, equalize, and vent process fluids makes them indispensable in ensuring safety, efficiency, and accuracy in operations. By selecting the right materials and maintaining them properly, industries can benefit from the reliability and longevity of 3-way manifold valves.

No comments:

Post a Comment