A 4-Way Manifold Valve plays a critical role in ensuring accurate measurement and safe operation within pressure-based systems. Designed primarily for use with pressure transmitters and pressure gauges, this valve system provides a reliable solution for isolating, calibrating, and venting pressure instruments. By combining four valves in a single unit, it offers enhanced operational efficiency and reduced installation complexity.

We are leading Instrumentation valves and accessories manufacturers in Mumbai, India

Showing posts with label manifold valves. Show all posts

Showing posts with label manifold valves. Show all posts

Saturday, 21 September 2024

Monday, 5 August 2024

4-Way Manifold Valves: Enhancing Efficiency and Control in Industrial Applications

In the realm of industrial instrumentation, the precision and reliability of valve systems play a crucial role in ensuring seamless operations. Among the various types of valves, 4-way manifold valves have emerged as a pivotal component in complex industrial processes. These valves, known for their versatility and efficiency, are designed to manage the flow of fluids and gases in intricate systems. In this article, we delve into the world of 4-way manifold valves, exploring their design, functionality, and applications, and highlighting why they are an essential choice for industries seeking optimal control and performance.

Understanding 4-Way Manifold Valves

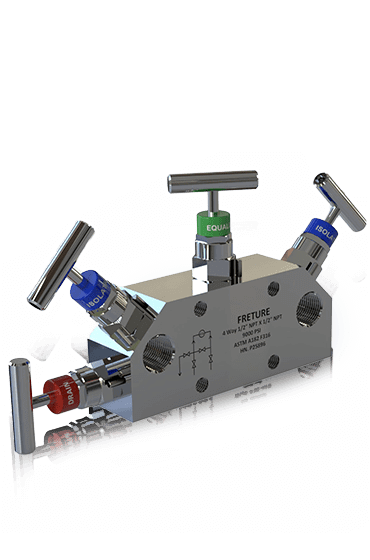

A 4-way manifold valve is a sophisticated device engineered to control the flow path of fluids or gases in multiple directions. Unlike traditional valves that offer limited flow control, 4-way manifold valves provide four distinct flow paths, enabling more complex routing of fluids within a system. This design is particularly advantageous in applications where precise control over flow direction is required, such as in hydraulic systems, pneumatic systems, and process control environments.

Key Features and Components

The design of 4-way manifold valves incorporates several key features that contribute to their superior performance:

Multiple Ports: As the name suggests, 4-way manifold valves have four ports, typically labeled as P (Pressure), T (Tank), A (Actuator), and B (Actuator). These ports allow the valve to direct the flow of fluids or gases to different parts of the system.

Balanced Design: Many 4-way manifold valves feature a balanced design, ensuring that the pressure is evenly distributed across the valve. This minimizes wear and tear, enhancing the valve's longevity and reliability.

High-Quality Materials: To withstand harsh industrial environments, 4-way manifold valves are constructed from durable materials such as stainless steel, brass, and other corrosion-resistant alloys. This ensures optimal performance even in challenging conditions.

Precision Engineering: The internal components of 4-way manifold valves are meticulously engineered to provide precise control over flow rates and directions. This precision is crucial for maintaining the integrity of industrial processes.

Functionality and Operation

The primary function of a 4-way manifold valve is to control the direction of fluid flow within a system. This is achieved through the manipulation of the valve's internal components, which can be manually operated or controlled by an actuator. Here’s a breakdown of how these valves operate:

Directional Control: By adjusting the position of the valve, the operator can direct the flow of fluid from the pressure port (P) to either of the actuator ports (A or B), and from the actuator ports to the tank port (T). This allows for versatile flow routing within the system.

Flow Regulation: 4-way manifold valves also provide precise regulation of flow rates, ensuring that the desired amount of fluid reaches each part of the system. This is particularly important in applications where maintaining specific flow rates is critical for process efficiency.

Isolation and Venting: These valves can also isolate sections of the system or vent fluids to prevent overpressure. This feature is essential for safety and maintenance purposes.

Applications of 4-Way Manifold Valves

The versatility and efficiency of 4-way manifold valves make them suitable for a wide range of industrial applications. Here are some key areas where these valves are commonly used:

Hydraulic Systems: In hydraulic machinery and equipment, 4-way manifold valves control the movement of actuators, ensuring precise positioning and operation. They are integral to the functioning of hydraulic presses, lifts, and other heavy machinery.

Pneumatic Systems: These valves are also used in pneumatic systems to control the flow of compressed air. Applications include air-powered tools, automation systems, and various types of pneumatic machinery.

Process Control: In industries such as oil and gas, chemical processing, and pharmaceuticals, 4-way manifold valves are used to manage the flow of liquids and gases through complex process pipelines. Their ability to provide precise control over flow rates and directions is crucial for maintaining process integrity.

HVAC Systems: In heating, ventilation, and air conditioning (HVAC) systems, 4-way manifold valves are used to regulate the flow of refrigerants and other fluids. This ensures efficient operation and temperature control within the system.

Advantages of 4-Way Manifold Valves

The adoption of 4-way manifold valves in industrial applications offers several significant advantages:

Enhanced Control: The ability to direct fluid flow in multiple directions provides greater flexibility and control over industrial processes. This can lead to improved efficiency and productivity.

Reduced Complexity: By consolidating multiple flow paths into a single valve, 4-way manifold valves simplify system design and reduce the need for additional components. This can lower installation and maintenance costs.

Improved Safety: The isolation and venting capabilities of these valves enhance system safety by preventing overpressure and allowing for safe maintenance procedures.

Durability and Reliability: Constructed from high-quality materials and designed for balanced operation, 4-way manifold valves offer long-term reliability and reduced downtime.

Freture Techno Pvt. Ltd.: Your Partner in Precision Valves

At Freture Techno Pvt. Ltd., we understand the critical role that precision valves play in industrial operations. Our 4-way manifold valves are designed and manufactured to meet the highest standards of quality and performance. With a commitment to innovation and customer satisfaction, we offer a range of valve solutions tailored to the specific needs of our clients.

Conclusion

In the ever-evolving landscape of industrial instrumentation, the importance of efficient and reliable valve systems cannot be overstated. 4-way manifold valves stand out as a versatile and effective solution for managing fluid flow in complex systems. Their unique design, coupled with precision engineering and high-quality materials, makes them an invaluable asset in various industrial applications. For industries seeking to enhance control, improve efficiency, and ensure safety, 4-way manifold valves from Freture Techno Pvt. Ltd. are the ideal choice. Embrace the future of industrial valve technology with our innovative solutions, and experience the difference in performance and reliability.

For more information on our range of 4-way manifold valves, visit Freture Techno Pvt. Ltd. today and discover how we can support your industrial needs.

Monday, 8 April 2024

Unveiling the Engineering Marvels: Instrumentation Valves in Industrial Precision

Within the intricate machinery of industrial processes, the unassuming yet crucial components known as instrumentation valves stand as sentinels of precision and control. These valves, meticulously crafted to handle fluids and gases with utmost accuracy, form the backbone of various industries. In this exploration, we delve into the world of instrumentation valves, unraveling their diverse types, functionalities, and the indispensable role they play in ensuring seamless operations. Additionally, we shine a spotlight on Freture Techno Pvt. Ltd., a trailblazer in the realm of instrumentation valves, renowned for their innovation and commitment to excellence.

Deciphering Instrumentation Valves:

Instrumentation valves serve as guardians of fluid flow, meticulously regulating the movement of liquids and gases within industrial systems. Unlike their conventional counterparts, instrumentation valves are engineered with precision to meet the exacting demands of modern industries, ranging from oil and gas to pharmaceuticals and beyond. These valves are characterized by their ability to operate under extreme conditions, maintaining efficiency and safety in the most challenging environments.

A Glimpse into the Varieties:

Needle Valves: With their slender, tapered design, needle valves offer unparalleled precision in flow control. By fine-tuning the position of a sharp needle within a conical seat, these valves allow for minute adjustments in flow rates, making them indispensable in applications where accuracy is paramount, such as laboratories and analytical instrumentation.

Ball Valves: Embodying simplicity and efficiency, ball valves employ a spherical closure mechanism to regulate flow. The rotation of a hollow ball within the valve body facilitates swift on/off control, making them ideal for high-pressure applications across industries, from chemical processing plants to water treatment facilities.

Check Valves: In the realm of fluid dynamics, check valves serve as gatekeepers, allowing flow in one direction while preventing backflow. Their straightforward design, often featuring a hinged flap or spring-loaded disc, ensures fluid directionality and prevents system contamination, making them indispensable in pipelines and pumping systems.

Manifold Valves: Simplifying complexity, manifold valves offer a centralized solution for fluid distribution in intricate instrumentation setups. By consolidating multiple ports and valves into a single block, these valves streamline installation, reduce leak points, and enhance system efficiency, particularly in industries requiring precise control over fluid distribution.

Choosing Wisely:

Selecting the right instrumentation valves entails a careful consideration of various factors, including:

Environmental Conditions: Assessing the temperature, pressure, and chemical compatibility requirements of the application to ensure that the chosen valves can withstand the rigors of the operating environment without compromising performance.

Flow Dynamics: Analyzing the desired flow characteristics, pressure drop, and flow control precision to determine the most suitable valve type for the application, whether it be a needle valve for precise metering or a ball valve for rapid shut-off.

Material Composition: Opting for valves constructed from corrosion-resistant materials that can withstand the corrosive effects of chemicals and harsh operating conditions, thereby ensuring longevity and reliability in service.

Compliance Standards: Verifying that the instrumentation valves adhere to industry standards and certifications, such as ASME, API, and ANSI, to guarantee quality, safety, and interoperability within industrial systems.

Freture Techno Pvt. Ltd.: Pioneering Excellence in Instrumentation Valves:

Freture Techno Pvt. Ltd. stands at the forefront of innovation and reliability in the realm of instrumentation valves, offering a diverse portfolio of high-quality solutions tailored to the unique needs of industrial applications. With a steadfast commitment to excellence, Freture Techno has earned the trust of customers worldwide, delivering precision-engineered valves that surpass expectations in terms of performance, durability, and safety.

Key Attributes of Freture Techno Instrumentation Valves:

Precision Craftsmanship: Freture Techno instrumentation valves are crafted with meticulous attention to detail, ensuring precise flow control, minimal leakage, and long-term reliability in even the most demanding operating conditions.

Comprehensive Range: From needle valves to ball valves, check valves, and manifold valves, Freture Techno offers a comprehensive array of instrumentation valves, catering to diverse industrial requirements and ensuring compatibility with various fluid handling systems.

Stringent Quality Assurance: Each Freture Techno valve undergoes rigorous testing and quality assurance measures to uphold the highest standards of quality, safety, and reliability. Compliance with international standards and certifications is ingrained in Freture Techno's manufacturing ethos.

Customer-Centric Solutions: Freture Techno collaborates closely with customers to develop bespoke valve solutions tailored to their specific applications and performance criteria. From custom materials to innovative designs, Freture Techno goes above and beyond to meet the evolving needs of industrial clients.

Conclusion:

Instrumentation valves stand as silent sentinels of precision and control within the bustling machinery of industrial processes, ensuring fluid flow with unparalleled accuracy and reliability. By understanding the diverse types of instrumentation valves, their functionalities, and the critical factors influencing valve selection, industry professionals can make informed decisions to optimize system performance and efficiency. With industry leaders like Freture Techno Pvt. Ltd. spearheading innovation and setting benchmarks for excellence, the future of instrumentation valves shines bright, promising continued advancements in fluid control technology.

Wednesday, 24 January 2024

Instrumentation valves play a crucial role in controlling the flow of fluids in various industrial processes, providing a means to regulate, isolate, and measure the movement of liquids and gases. These valves are vital components in high-pressure applications, where precision and reliability are paramount. Let's delve deeper into the world of instrumentation valves, understanding their types, functions, and importance in industrial settings.

Types of Instrumentation Valves:

Needle Valves:

Function: Precision flow control in low-flow applications.

Features: Fine-threaded stems for accurate adjustments, ideal for calibration and instrumentation systems.

Ball Valves:

Function: On/Off control for a wide range of fluids.

Features: Quick quarter-turn operation, minimal pressure drop, and versatile applications.

Check Valves:

Function: Prevents backflow, maintaining a unidirectional flow.

Features: Essential for systems where backflow could damage equipment or compromise accuracy.

Gate Valves:

Function: Full open or fully closed positions.

Features: Robust construction, suitable for high-pressure and high-temperature applications.

Manifold Valves:

Function: Combines multiple valves into a single body for space and cost efficiency.

Features: Streamlines fluid distribution and simplifies system design.

Functions and Importance:

Flow Control:

Instrumentation valves enable precise regulation of fluid flow, critical in applications where accurate measurements or specific flow rates are required.

Isolation:

Valves act as isolators, allowing technicians to safely perform maintenance or repairs without shutting down an entire system.

Pressure Regulation:

In high-pressure environments, instrumentation valves are designed to handle and regulate pressure, preventing overloads and ensuring system integrity.

Safety:

Properly selected and maintained valves contribute to the overall safety of industrial processes by preventing leaks, backflow, and other potential hazards.

Accuracy in Measurement:

Valves play a key role in maintaining accuracy in measurement devices such as pressure gauges and flow meters, ensuring reliable data for process control.

Considerations in Selecting Instrumentation Valves for High-Pressure Applications:

Material Compatibility:

Choose materials that resist corrosion and erosion, ensuring the longevity of the valve in harsh environments.

Pressure and Temperature Ratings:

Select valves with appropriate pressure and temperature ratings to match the demands of the application, preventing failure under extreme conditions.

End Connections:

Consider the type of end connections (flanged, threaded, or welded) based on system requirements and installation preferences.

Sealing Mechanism:

Evaluate the sealing mechanism (soft-seated or metal-seated) based on the specific needs of the application for leak-tight performance.

Testing and Certification:

Ensure that valves comply with industry standards and undergo rigorous testing to guarantee their reliability in high-pressure settings.

In conclusion, instrumentation valves are the unsung heroes of high-pressure applications, facilitating precise control and ensuring the safety and efficiency of industrial processes. Proper selection, regular maintenance, and adherence to industry standards are essential in harnessing the full potential of these valves and taming the challenging environment they operate in.

Subscribe to:

Posts (Atom)

Understanding 5 Way Manifold Valves: Types, Functions, and Industrial Applications

A 5 Way Manifold Valve is designed to support precise measurement and control in differential pressure applications. Commonly used in inst...

-

A 5 Way Manifold Valve is designed to support precise measurement and control in differential pressure applications. Commonly used in inst...

-

Safety is a core priority in industries where high-pressure systems, hazardous substances, and complex processes are involved. To meet thes...

-

High-pressure systems demand equipment that can handle extreme conditions while maintaining optimal performance. High-pressure needle valves...