Double Block and Bleed (DBB) valves have become essential components in industries where safety and reliability are paramount. Designed to isolate and depressurize equipment, these valves ensure that hazardous fluids do not escape during critical maintenance or inspection processes.

What Are Double Block and Bleed Valves?

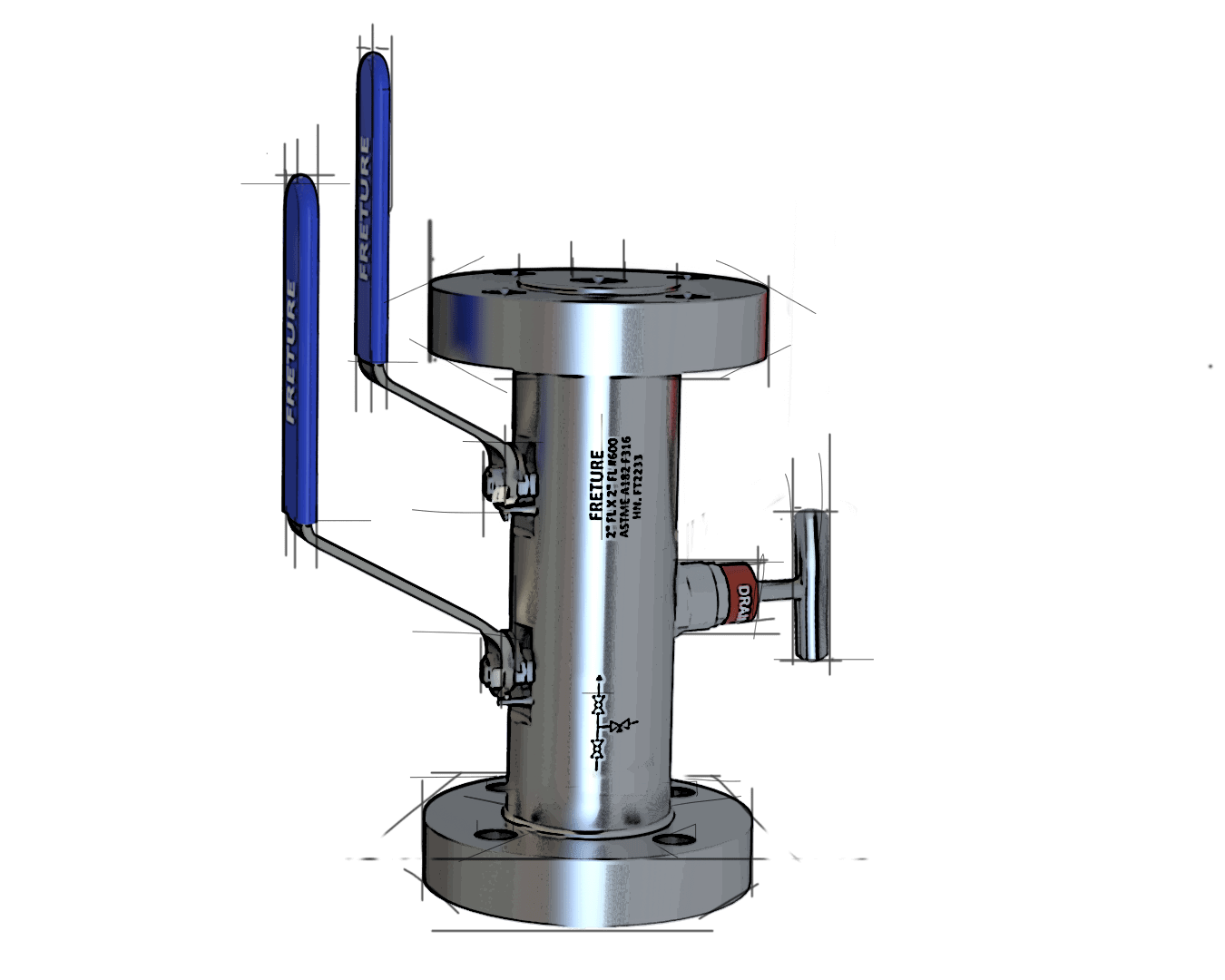

A Double Block and Bleed valve system consists of two sealing mechanisms and a bleed valve positioned between them. This design enables the isolation of fluids or gases on both sides, ensuring that the area between the two seals can be safely depressurized and drained. Unlike traditional valves, DBB valves provide an extra layer of protection, making them ideal for industries like oil and gas, chemical processing, and power generation.

Key Features of DBB Valves

DBB valves are often preferred in applications where fluid or gas leakage could cause environmental damage, safety risks, or operational downtime. Some critical features include:

- Dual isolation: The ability to isolate on both sides of the valve ensures complete separation of fluid or gas.

- Bleed function: This allows operators to release pressure safely between the two blockages, providing a safe environment for maintenance or inspection.

- Compact design: DBB valves often replace multiple traditional valves, reducing space and the complexity of piping systems.

Types of Double Block and Bleed Valves

Different types of DBB valves are available to meet varying industrial needs. The most common types include:

- Ball DBB Valves: Known for their quick operation and reliability, ball DBB valves are used in both low and high-pressure systems.

- Needle DBB Valves: These offer precise flow control and are ideal for systems that require more gradual pressure relief.

- Plug DBB Valves: Frequently used in the oil and gas industry, plug DBB valves are suitable for handling high-pressure and corrosive fluids.

Applications of Double Block and Bleed Valves

DBB valves play a crucial role in various industries. Some notable applications include:

- Oil and gas pipelines: These valves help isolate sections of a pipeline for safe maintenance, ensuring that no fluids or gases are leaked.

- Refineries and petrochemical plants: DBB valves are used to prevent cross-contamination of products during different stages of the refining process.

- Power generation: These valves maintain safe operation during high-temperature processes, preventing leaks in steam and cooling systems.

Benefits of DBB Valves

One of the most significant advantages of using DBB valves is the enhanced safety they provide. By isolating hazardous fluids or gases, these valves prevent potentially dangerous leaks that could lead to environmental harm or workplace accidents. Furthermore, the use of a single DBB valve in place of multiple valves reduces installation costs and simplifies maintenance procedures.

Double Block and Bleed valves have become an indispensable part of industrial processes where safety, reliability, and efficiency are required. When choosing DBB valves, it is crucial to consider the specific needs of your system and the types of fluids or gases being handled. For industries seeking durable and high-performance DBB valves, Freture Techno Pvt. Ltd. offers a range of options designed to meet the most demanding operational standards.