Many will wonder what is DBB valve is. Double Block and Bleed (DBB) Valve is a type of valve that serves the purpose of isolating and decreasing pressure in a system. It is made up of two shut-off valves or ‘blocks’ that are connected by a pipe or conduit. The pipes are separated by a valve in between, often referred to as a ‘bleed’ valve. When all three components are closed, it enables the system to be shut down and isolated from any increase in pressure.

This type of valves have been used in numerous industries, including oil and gas, petrochemical, power generation, maritime, mining and chemical production. The reliability of DBB valves makes them ideal for use in high-pressure systems that contain highly volatile substances.

By combining two shut-off valves and a bleed valve into one unit, DBB valves offer a number of benefits to users. These are easy to install and maintain, making them cost-effective when compared to other types of valves; they prevent leakage due to their advanced sealing design; and they require minimal pressure drop, allowing for more efficient operation.

There are several different types of double block and bleed valve available on the market, including ball valves, gate valves, globe valves, and needle valves. Each type of valve has unique features and advantages that make it suitable for different applications and industries.

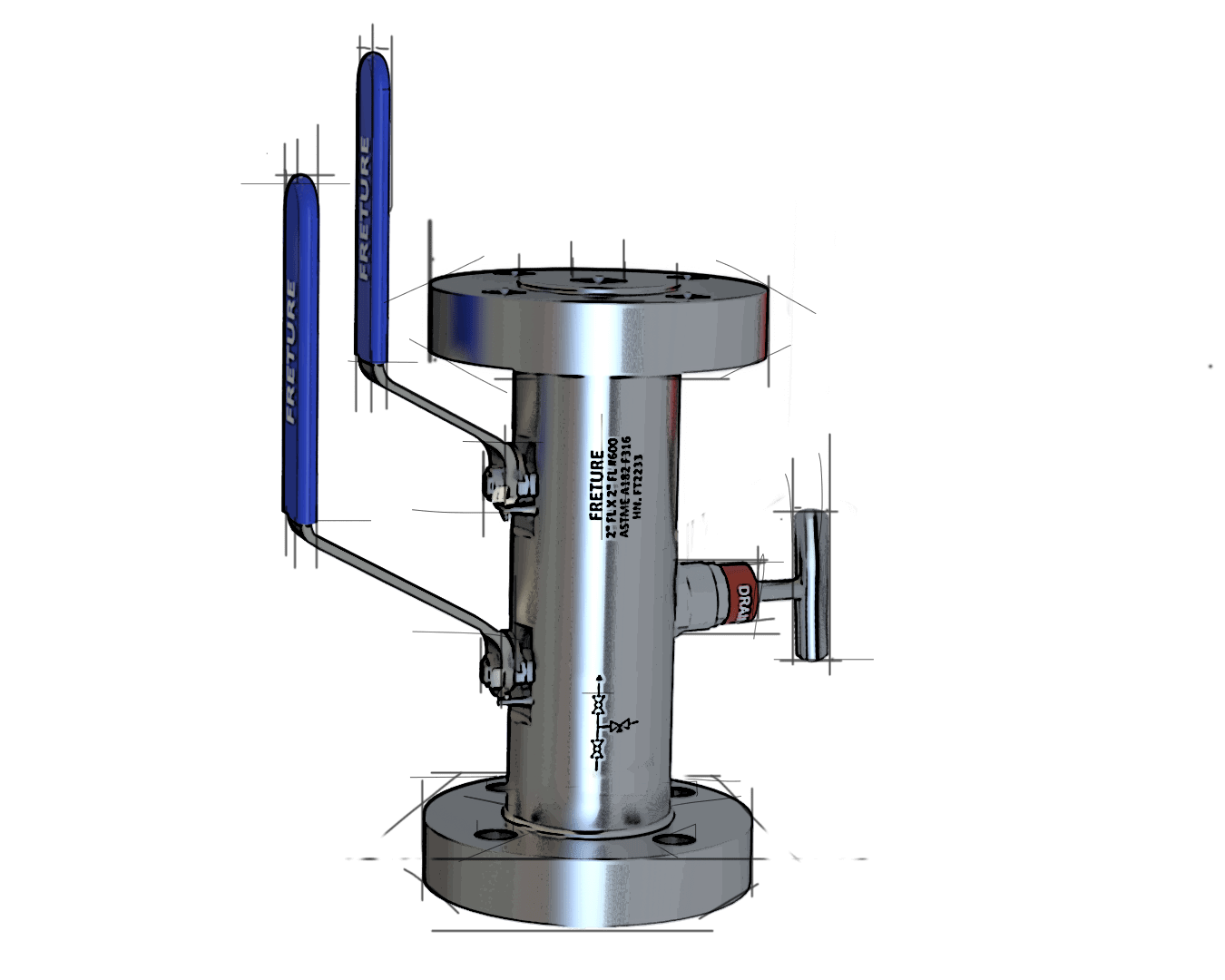

DBB ball valve

Ball Valves

Double ball valve uses a hollow, perforated and pivoting ball to control the flow of liquids or gas. They are also used for isolation and control of high-pressure systems, in fire sprinkler systems, and various industrial processes. A hole runs through the ball inside the valve, allowing fluid to flow through when the hole is in line with the inlet and outlet ports. When the valve is rotated 90 degrees, the hole is perpendicular to the ports, and no fluid can flow.

DBB ball valve is primarily used in applications where tight shut-off is required. This makes them well suited for water regulation, oil refineries, natural gas production, and chemical processing plants.

Gate Valves

Gate valves are a type of valve used to control the flow of liquids and gasses. They consist of a rectangular gate that slides up or down within an enclosed chamber, thereby allowing or blocking passage through the valve. Gate valves are used in many applications from engineering to plumbing, and have become very popular in the past few decades due to their reliability and affordability.

Gate valves vary in size, depending upon the size of the opening they are designed to control. The larger the opening, the larger and stronger the gate must be. Some valves also come equipped with reinforced seats for increased durability.

Check Valves

Another type of DBB valve is check valves. These are devices used to prevent the backflow of fluid in a piping system. They act as one-way valves and allow pressure or fluid to flow only in one direction. Check valves are made of corrosion-resistant materials, making them ideal for use in water, fuel, oil, and other piping systems.

Check valves are an essential part of any fluid system as they help protect against expensive damage due to backpressure and also help keep fluid flowing in the right direction. They are commonly used in industrial applications such as cooling systems, fuel distribution, and chemical process plants.

Globe Valves

This is a type of valve used to regulate the flow or pressure in a piping system. Globe valves are typically used in industrial systems due to their accurate control of flowing liquids, vapors, and gasses. The core of the globe valve design consists of a disk-shaped closure element which can be manipulated using a stem attached to the top of the valve body.

Globe valves are most commonly used in applications where precision flow regulation is required, such as within steam boilers and air conditioning systems. They are also ideal for regulating the flow rates of corrosive materials, such as acids and alkalis, due to a number of features that make them resistant to these corrosive substances.

Butterfly Valves

Butterfly valves are mechanical devices used to regulate the flow of gasses and liquids in industrial process lines. They are typically used in applications such as oil and gas pipelines, water treatment plants, and chemical plants. Butterfly valves are rotary valves that use two disks connected by a stem or shaft which can be used to toggle the access to a passageway by varying the valve’s position relative to the pipe.

Butterfly valves come in many different shapes, sizes and materials depending on the application. Dombor, one of the butterfly valve manufacturer, offers valves depending on the valve size; butterfly valves can be operated manually, pneumatically or electrically.

Plug Valves

A plug valve is a quarter-turn rotary valve used to control the flow of fluids in many industries, including oil and gas production, petrochemical plants, chemical processing, food and beverage, and water treatment. The plug has a port or opening which can be opened or closed by rotating the plug. This type of valve is ideal for applications where quick shutoff is necessary.

Plug valves are typically operated manually using a lever or a handwheel. More sophisticated versions may use an automated actuator such as an electric motor or pneumatic system. These automated versions are used when precise control is needed or where remote operation is desired.

Diaphragm Valves

This is a type of valve used to control the flow of liquids and gasses. It consists of a flexible membrane which is clamped between two solid seatings. The membrane is opened or closed by the application of either an external or an internal force. When open, the diaphragm allows fluid to pass through the valve; when closed, it seals off the opening and prevents fluid from passing through.

Diaphragm valves are primarily used for on/off control, most commonly in industrial applications. They are also used in applications where tight shutoff is important, such as in medical and laboratory equipment.

Piston Valves

A piston valve is a type of valve used to regulate systems that control the flow of liquid or gas. They are common in many industrial applications, such as compressors and boilers. Piston valves can be described as a sliding sleeve with a collar attached to the sleeve, which controls the flow of the medium. The collar can then be opened and closed by either manually or electronically turning the sleeve through the use of an actuator or motor.

Piston valves provide several advantages over other types of valves. The most obvious one is their ability to open and close quickly and accurately, allowing precise control of fluid flow. This makes them ideal for regulating dynamic fluid systems and processes like water, steam, and oil.

How do Double Block & Bleed Ball Valves Work?

When asking what is a block and bleed valve is and how it works, well, double block and bleed ball valve works by utilizing a circular ball with a hole in the center that can be rotated to control the flow of fluids or gasses. These valves consist of two separate ball valves and a bleed valve in between them, which allows for the isolation of the upstream and downstream piping.

Double block and breed ball valve

In the open position, the spherical ball is tilted so that the hole in the ball is aligned with the upstream and downstream piping, allowing fluid or gas to flow through the valve. When the valve needs to be closed, the ball is angled 90 degrees so that the hole in the ball is perpendicular to the piping, effectively blocking the flow of fluid or gas.

To double block and bleed, both ball valves are shut, and the bleed valve is opened to allow any trapped fluid or gas between the two ball valves to be vented out. This ensures that the piping between the two ball valves is completely isolated and free from any fluid or gas pressure.

Double block & bleed ball valve is commonly used in oil and gas, chemical, and pharmaceutical industries, where safety and reliability are critical.