Double Block and Bleed (DBB) Valves play an essential role in high-risk applications, especially in industries such as oil and gas, petrochemicals, and water treatment. These valves offer dual isolation and pressure relief, ensuring system safety and reliability during maintenance or shutdown procedures. Understanding the types of DBB valves is crucial for selecting the right solution for your application.

Types of Double Block and Bleed Valves

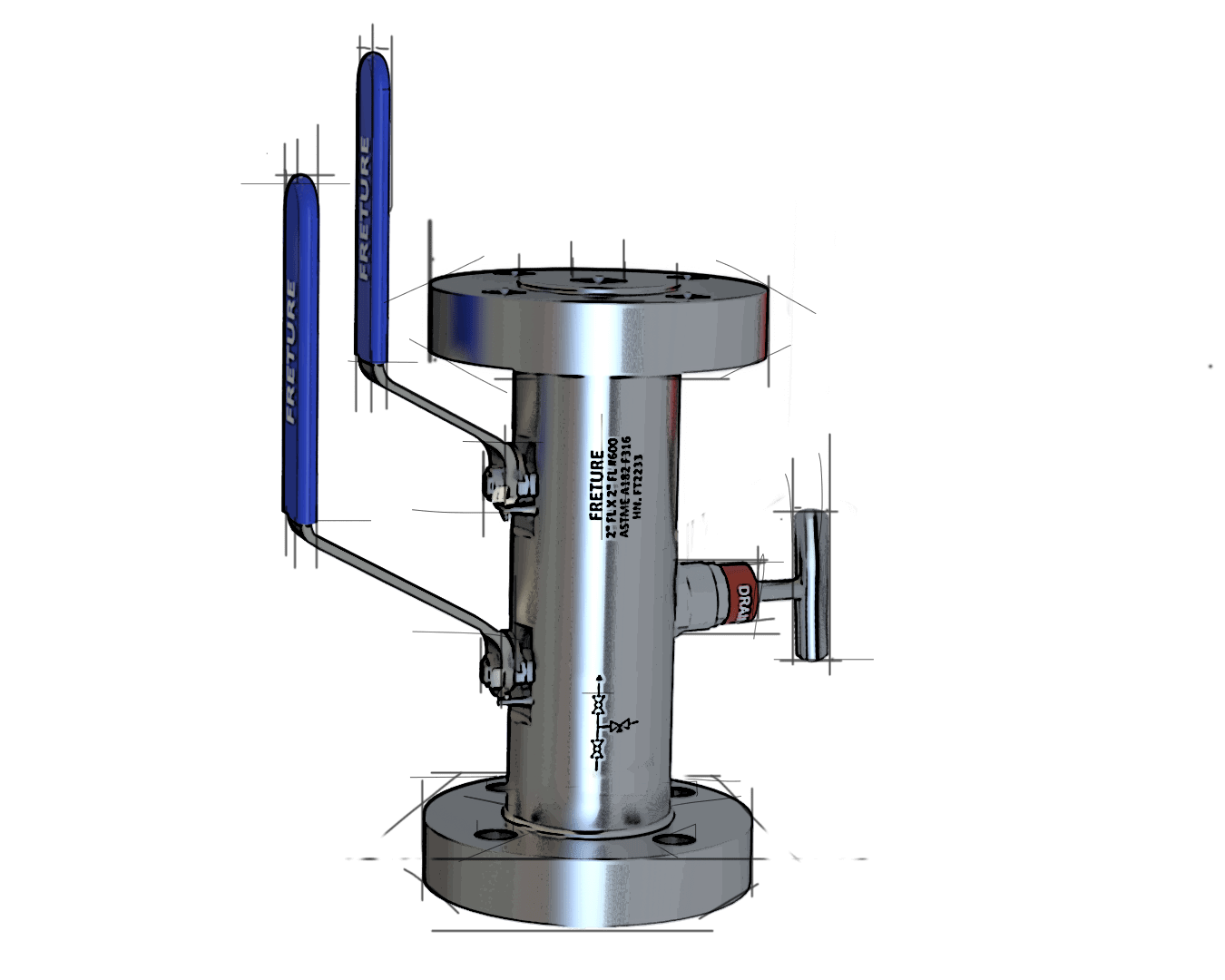

Ball Double Block and Bleed Valves: As one of the most commonly used DBB valve types, ball valves feature two ball elements that act as independent seals. They are used in high-pressure applications, particularly in the oil and gas industry, due to their durability and ease of operation.

Gate Double Block and Bleed Valves: Gate DBB valves use a flat or wedge-shaped gate to block fluid flow. They are ideal for environments where a tight shutoff is required, such as in pipeline systems where full isolation is necessary for maintenance.

Needle Double Block and Bleed Valves: Designed for precision, needle DBB valves offer excellent control over small volumes of fluids. These valves are perfect for instrumentation systems and are often used in industries that require precise control over fluid flow.

Plug Double Block and Bleed Valves: Featuring a cylindrical or tapered plug, these valves provide quick operation and are commonly used in applications where rapid isolation is required. Their simple design and ease of maintenance make them ideal for natural gas systems.

|

| Double Block and Bleed Valves Manufacturers in India |

Features of Double Block and Bleed Valves

DBB valves are defined by their robust design and functionality. Some key features include:

- Double Isolation: Ensuring complete isolation on both sides of the valve, these valves are crucial for safety in systems handling hazardous materials.

- Bleed Functionality: The central bleed valve allows for pressure relief, preventing trapped pressure from causing system failures.

- High Durability: DBB valves are often made from materials such as stainless steel and carbon steel, capable of withstanding high temperatures and corrosive fluids.

- Compact Construction: Many DBB valves offer a compact, space-saving design without sacrificing functionality, making them easier to install in confined spaces.

- Compliance with Industry Standards: These valves are built to meet stringent safety and environmental regulations in sectors like oil and gas, ensuring compliance with international standards.

Advantages of Double Block and Bleed Valves

- Enhanced Safety: By providing dual isolation, DBB valves offer a higher level of safety, preventing leaks and system failures in high-pressure environments.

- Reduced Maintenance Time: DBB valves allow for faster maintenance and shutdown processes by isolating sections of the system without disrupting the entire operation.

- Cost-Effective Solutions: Using DBB valves reduces the need for multiple valve installations, leading to lower material and labor costs.

- Environmental Protection: DBB valves help prevent the release of harmful substances, contributing to environmental safety by containing leaks within the system.

Freture Techno Pvt. Ltd. is a top-tier manufacturer of Double Block and Bleed Valves in Mumbai, India. Their expertise and dedication to innovation make them a trusted partner for industries requiring high-quality valve solutions.

No comments:

Post a Comment