In industries where high pressures and precise control are crucial, high pressure needle valves play a vital role. These valves are designed to regulate fluid flow with accuracy and reliability, making them an essential component in various applications. In this article, we will explore the features, benefits, and applications of high pressure needle valves.

Key Features

They are engineered to provide precise control over fluid flow. Some of the key features of these valves include:

- Precise Control: They offer precise, incremental control over fluid flow, allowing for accurate regulation of pressure and flow rate.

- High Pressure Capability: These valves are designed to withstand high pressures, making them suitable for applications where pressures exceed 15,000 psi.

- Low Leakage: They are designed to provide low leakage rates, minimizing waste and reducing the risk of environmental contamination.

Applications of High Pressure Needle Valves

They are used in various industries, including:

- Oil and Gas: These valves are used in oil and gas production, processing, and transportation to regulate pressure and flow rate.

- Chemical Processing: They are used in chemical processing plants to control the flow of corrosive and toxic fluids.

- Power Generation: These valves are used in power generation plants to regulate pressure and flow rate in high-pressure steam systems.

Benefits of High Pressure Needle Valves

They offer several benefits, including:

- Improved Accuracy: These valves provide precise control over fluid flow, allowing for accurate regulation of pressure and flow rate.

- Increased Reliability: They are designed to withstand high pressures and corrosive fluids, reducing the risk of failure and downtime.

- Reduced Maintenance: These valves require minimal maintenance, reducing maintenance costs and downtime.

Conclusion

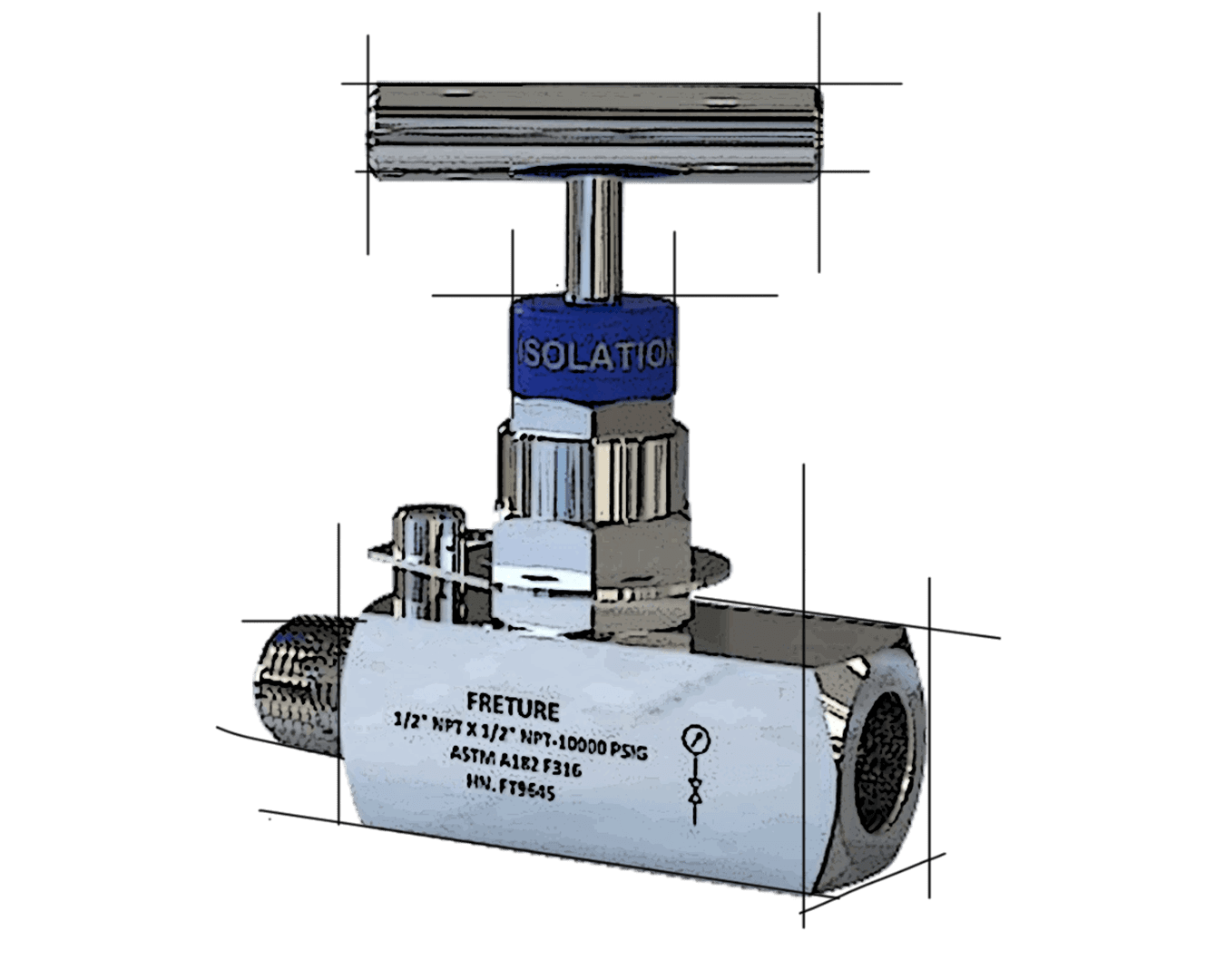

In conclusion, they are a reliable and efficient solution for demanding applications where high pressures and precise control are required. With their precise control, high pressure capability, and low leakage, these valves are an essential component in various industries. Freture Techno is a leading manufacturer of high pressure needle valves, offering high-quality valves that meet the highest industry standards.

No comments:

Post a Comment