A 5 Way Manifold Valve is designed to support precise measurement and control in differential pressure applications. Commonly used in instrumentation systems, these valves allow the controlled flow of process media while enabling isolation, equalization, venting, and calibration.

In pressure instrumentation systems, the role of the manifold valve is crucial. By consolidating multiple valve functions into a single compact unit, it simplifies installation and ensures system integrity. Especially when paired with differential pressure transmitters, 5 way manifold valves ensure consistent and safe operation in complex industrial environments.

Working Principle and Functions

The primary function of a 5 way manifold valve is to manage the flow paths between the pressure instrument and the process line. Five ports are utilized to perform the following key operations:

-

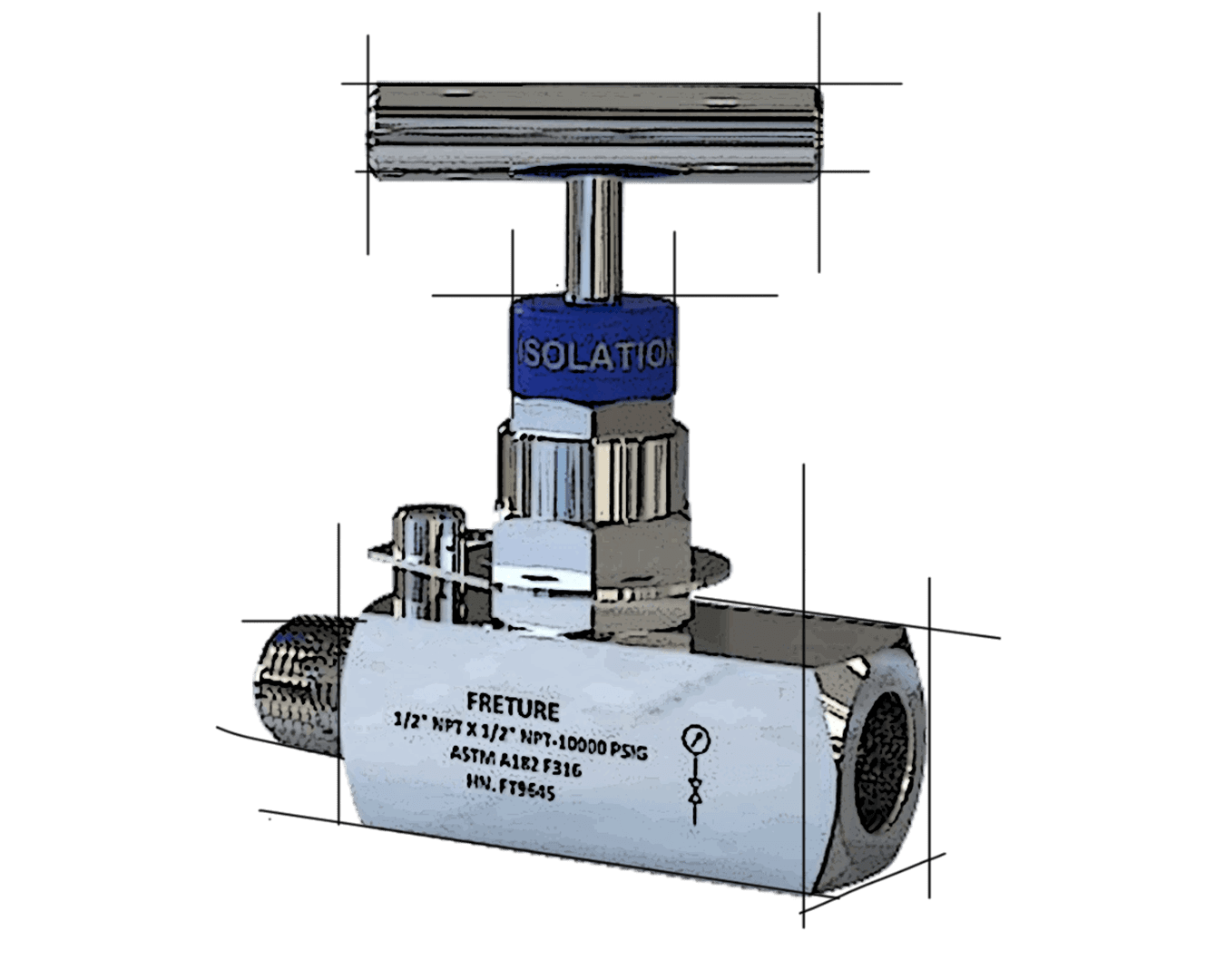

Isolation: Process pressure can be isolated from the transmitter using block valves to enable safe maintenance.

-

Equalization: Equalizer valves are used to balance pressure across the high and low sides of the transmitter before calibration or during zeroing.

-

Venting: The venting of pressure on either or both sides of the transmitter is enabled for safe removal or calibration.

-

Calibration: Through specific configurations, calibration processes are facilitated without removing the instrument.

These functions make the valve integral to the performance and longevity of pressure transmitters and gauges. By providing control over the pressure environment, errors in readings are minimized and transmitter life is extended.

Types of 5 Way Manifold Valves

Remote mount 5 way manifold valves are designed for installations where the valve and transmitter are located apart from each other. Tubing or impulse lines connect the valve to the instrument, offering flexibility in layout.

Direct Mount

Direct mount designs allow the valve to be connected directly to the transmitter. This reduces potential leak points and is ideal where space is limited or where minimal lag time is desired between the process and measurement.

Traditional vs Compact Design

Traditional designs feature extended body lengths for ease of access, while compact manifold valves are optimized for installations with space constraints. Both serve the same function, with the compact version gaining preference in modern skid-based installations.

End Connection Types

Various end connections are available to suit system requirements:

-

Flanged ends for high-integrity process connections

-

Threaded ends (NPT, BSP) for quick installation

-

Compression fittings for tubing-based systems

Each connection type is selected based on pressure rating, installation preferences, and system compatibility.

Materials and Design Standards

5 Way Manifold Valves are manufactured in a range of materials to ensure compatibility with different process fluids and environmental conditions. Commonly used materials include:

-

Stainless Steel (SS 316, SS 304) for corrosion resistance

-

Carbon Steel for general-purpose use

-

Exotic Alloys such as Hastelloy, Monel, or Inconel for aggressive environments

These valves are designed to withstand high pressures, often rated up to 6000 psi or more. Operating temperature ranges are also considered, with seals and materials selected to endure extreme temperatures without compromising performance.

Design and manufacturing are governed by international standards such as ANSI, ASME, and ISO, ensuring safety, reliability, and interchangeability across industrial applications.

Industries Where 5 Way Manifold Valves Are Used

Oil & Gas

In upstream and downstream applications, 5 way manifold valves are used with differential pressure transmitters for flow measurement and wellhead monitoring.

Petrochemical and Chemical

Corrosive and hazardous media in these industries demand robust and leak-tight manifold valves, making stainless steel and alloy options essential.

Power Generation

Used in steam and water monitoring systems, these valves play a role in safety assurance and process efficiency in thermal and nuclear power plants.

Pharmaceutical

Clean environments in pharma manufacturing require manifold valves for precise pressure control and instrumentation, often in hygienic-grade materials.

Water Treatment

Water filtration and treatment facilities rely on manifold valves for monitoring pressure differentials across filters and membranes.

Food and Beverage

Pressure monitoring in process lines ensures consistency and quality in production. Valves with sanitary fittings and food-grade materials are typically used.

Advantages and Reliability

The reliability of 5 way manifold valves in instrumentation has made them indispensable in process industries. Key advantages include:

-

Leak-tight Performance: Precision machining and high-quality seals ensure secure operation under pressure.

-

Corrosion Resistance: Material selection prevents degradation, even in harsh environments.

-

Maintenance Efficiency: Fewer connections mean less risk of leaks and easier servicing.

These characteristics contribute to reduced downtime, safer operation, and long-term cost efficiency.

Conclusion

The 5 Way Manifold Valve has been recognized as a cornerstone component in precision instrumentation across a wide range of industries. With their ability to streamline multiple operations—such as isolation, venting, and calibration—into a single compact design, their value in maintaining system integrity and accuracy cannot be overstated.

For dependable and high-performance manifold valves, Freture Techno Pvt. Ltd. is trusted as a leading manufacturer in India. Offering a comprehensive range of 5 way manifold valves built to international standards, Freture ensures quality, durability, and efficiency across every application.