In industries where precision and safety are paramount, such as oil and gas, petrochemical, and power generation, reliable instrumentation and control systems are crucial. One such component gaining traction in these sectors is the Monoflange Valve. Designed to streamline operations, enhance safety, and reduce potential leak paths, Monoflange valves have become a preferred choice for engineers and operators. This article delves deep into Monoflange valves, exploring their types, configurations, and applications.

What Are Monoflange Valves?

Monoflange valves are compact, integrated valve solutions that combine various valve functions into a single block. They are typically used for applications where space constraints exist or where reducing potential leak points is critical. By combining isolation, venting, and drain functions, Monoflange valves reduce the need for multiple connections, minimizing weight, space, and installation time. These valves are widely utilized in instrumentation, where process pressure measurement, sampling, and maintenance activities require precise control.

The Monoflange valve’s design significantly reduces the number of potential leak paths compared to conventional multi-valve arrangements. This makes them particularly useful in industries where leak detection and emission control are of high importance.

Key Benefits of Monoflange Valves

Monoflange valves offer several advantages, making them a popular choice for demanding applications:

- Space-Saving Design: By combining multiple valves into a single block, Monoflange valves reduce the overall footprint, making them ideal for applications with limited space.

- Enhanced Safety: Fewer connections and potential leak points mean a lower risk of leakage, which is critical for hazardous applications like oil and gas.

- Reduced Weight: By eliminating the need for multiple valve assemblies, Monoflange valves contribute to weight reduction in piping systems.

- Ease of Installation and Maintenance: Fewer components mean fewer connections to make and monitor, simplifying both installation and maintenance.

- Minimized Leak Paths: The integrated design ensures that fewer joints and connections are required, reducing the potential for leaks.

Types of Monoflange Valves

Monoflange valves are available in various configurations to suit specific application needs. Below, we explore the main types of Monoflange valves and their typical use cases.

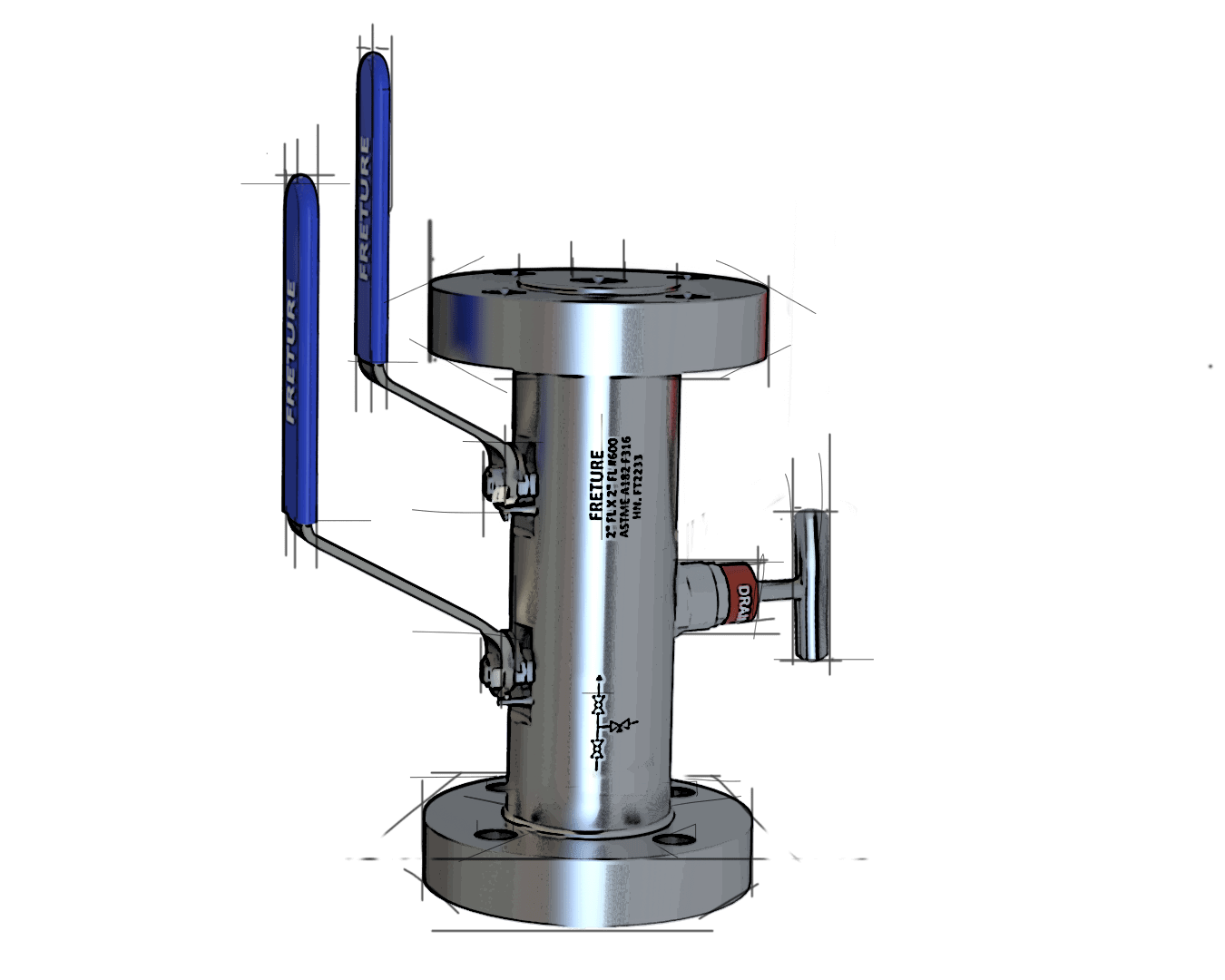

1. Ball Valve Monoflange

Ball Valve Monoflange is one of the most commonly used types due to its simple and effective design. It incorporates a ball inside the valve body, which rotates to control the flow of fluid or gas. When the ball is aligned with the flow path, the valve is open; when rotated 90 degrees, the valve closes, ensuring a tight shutoff.

Key Features:

Quarter-turn operation: The ball valve design allows for quick and easy operation with a simple quarter-turn movement.

Full bore flow: Ball valves provide full bore, meaning there is minimal pressure drop across the valve, ensuring efficient fluid transfer.

High shutoff integrity: The ball valve's tight seal reduces the risk of leakage, making it suitable for high-pressure applications.

Applications: Ball Valve Monoflanges are commonly used in high-pressure systems, such as those found in oil and gas pipelines, where a reliable and leak-proof shutoff is required.

2. Globe Type Needle Valve Monoflange

The Globe Type Needle Valve Monoflange is designed for precise flow control. It operates by adjusting the position of a needle-shaped disc that moves in and out of the valve seat, allowing for fine control over the flow of fluid or gas.

Key Features:

Precision control: The needle valve design allows for highly accurate control of fluid flow, making it ideal for instrumentation applications where precise regulation is required.

High pressure tolerance: Globe type needle valves can handle high-pressure conditions, making them suitable for challenging environments.

Compact design: Like other Monoflange valves, the globe type needle valve is designed to minimize space and weight in the system.

Applications: These valves are commonly used in applications requiring fine control of flow rates, such as in chemical processing plants or for sampling in the oil and gas industry.

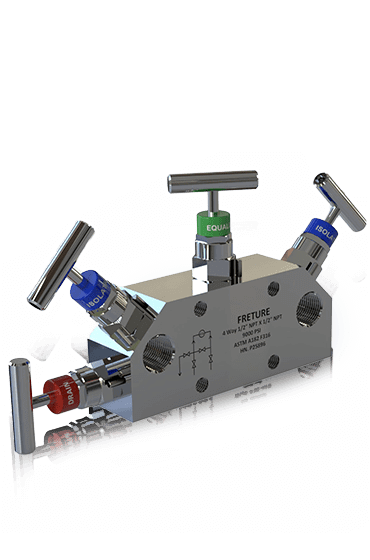

3. Ball-Needle-Ball Type Monoflange

The Ball-Needle-Ball Type Monoflange combines the features of both ball and needle valves into a single unit. This configuration typically includes two ball valves for isolation purposes and a needle valve in between for precise control or venting.

Key Features:

Dual isolation: The two ball valves provide excellent isolation, allowing operators to safely block off flow during maintenance or repairs.

Precise control: The needle valve allows for fine adjustments of fluid flow or pressure release, offering both control and safety in critical operations.

Versatile functionality: This type of Monoflange is particularly useful in systems that require both tight shutoff and fine flow control in one unit.

Applications: The Ball-Needle-Ball Type Monoflange is ideal for applications that require isolation and precise control, such as in pressure measurement systems or instrumentation lines in high-pressure environments.

Monoflange Valve Configurations

Monoflange valves are available in various configurations to suit specific operational needs. The most common configurations include:

1. Monoflange Valve: Single Isolation

In the Single Isolation Monoflange Valve configuration, there is a single isolation valve, usually a ball or needle valve. This configuration is ideal for applications where isolation is required but venting or draining is not a critical function.

Applications: Single isolation valves are typically used in non-critical systems or where space constraints make a single valve assembly preferable.

2. Monoflange Valve: Isolation Drain

The Isolation Drain Monoflange Valve includes an isolation valve and a drain valve in one assembly. The drain valve is often used to release pressure or purge gases or liquids from the system.

Applications: This configuration is commonly used in high-pressure systems, such as oil and gas pipelines, where draining fluids is necessary for maintenance or safety.

3. Monoflange Valve: Isolation-Isolation-Drain

The Isolation-Isolation-Drain Monoflange Valve configuration includes two isolation valves and a drain valve. This design provides dual isolation, which is essential in critical applications where maximum safety and leak prevention are required. The drain valve allows for safe venting or draining of fluids from the system.

Applications: This configuration is used in critical applications such as in high-pressure instrumentation systems or for measuring and sampling purposes in oil and gas operations.

Materials and Construction

Monoflange DBB Valves are typically constructed from materials like stainless steel, carbon steel, or exotic alloys such as Inconel, depending on the application’s corrosive and pressure conditions. The choice of material is crucial in ensuring the valve’s longevity and performance in harsh environments, such as offshore oil rigs or chemical processing plants.

The valves are also designed to meet stringent safety and performance standards, including ASME, ANSI, and API standards, ensuring their reliability in demanding industrial applications.

Applications of Monoflange Valves

Monoflange valves are widely used in industries where precise control and safety are critical. Some key applications include:

- Oil and gas: For pressure measurement, sampling, and instrumentation in high-pressure environments.

- Petrochemical: In systems requiring fine flow control and isolation for sampling or maintenance.

- Power generation: For controlling and monitoring fluids in boiler systems or steam lines.

- Chemical processing: In applications requiring the precise control of aggressive or corrosive fluids.

Monoflange valves are an essential component in various industries, offering a compact, reliable solution for fluid and gas control. Whether you need a single isolation valve for basic applications or a more complex isolation-isolation-drain configuration for critical operations, Monoflange valves can provide the safety and performance needed in demanding environments.

For high-quality Monoflange valves, consider purchasing from Freture Techno Pvt. Ltd., a leading manufacturer of industrial valves in Mumbai, India. With a commitment to precision engineering and innovation, Freture Techno Pvt. Ltd. offers a range of Monoflange valves designed to meet the most stringent industrial requirements.